Time:2025-04-24 Views:1 source:News

Pogopin connectors play a crucial role in high - speed rail systems, where reliable electrical connections are essential for the safe and efficient operation of various components and systems. High - speed rail environments are characterized by high - speed movement, significant vibrations, and exposure to a wide range of environmental conditions, such as temperature fluctuations, humidity, and dust. Pogopin connectors are well - suited to meet these demanding requirements.

One of the key applications of pogopin connectors in high - speed rail is in the electrical connection of onboard systems. These include the control systems that manage train operations, such as speed control, braking, and signaling. Pogopin connectors provide a secure and stable connection for the transfer of electrical signals and power between different control modules, ensuring that the train's control systems operate smoothly and accurately. The spring - loaded design of pogopin connectors allows them to maintain contact even during the intense vibrations generated by the high - speed movement of the train, preventing intermittent connections that could lead to system malfunctions or safety hazards.

In addition, pogopin connectors are used in the connection of communication systems on high - speed rail. This includes both the internal communication systems for train staff and the external communication systems for passenger services, such as Wi - Fi and mobile network connectivity. Reliable electrical connections are crucial for seamless communication, and pogopin connectors can provide the necessary signal integrity and stability. Their ability to withstand environmental factors, such as humidity and dust, ensures that the communication systems remain operational in different weather conditions.

Pogopin connectors are also employed in the power supply systems of high - speed rail. They are used to connect power sources, such as batteries and generators, to various electrical components on the train, including lighting, air - conditioning, and propulsion systems. The high - current - carrying capacity and low contact resistance of pogopin connectors enable efficient power transfer, reducing energy losses and ensuring the reliable operation of the train's electrical systems.

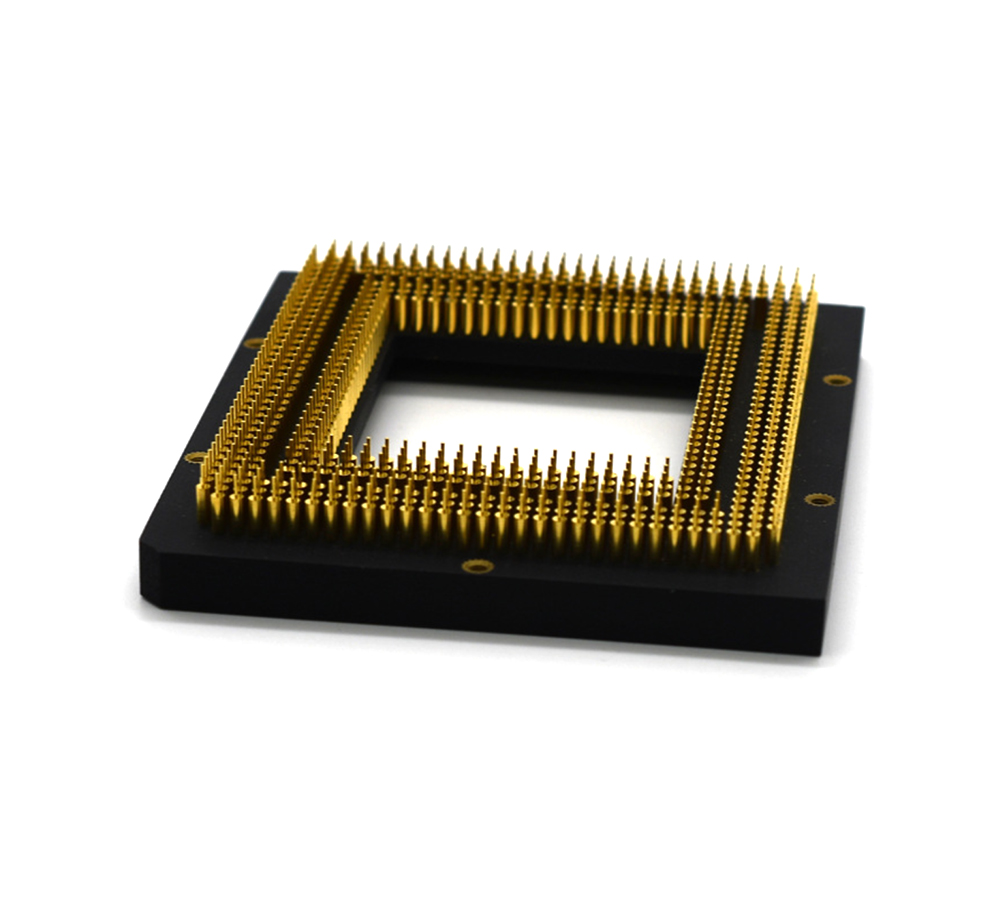

The design and selection of pogopin connectors for high - speed rail applications are carefully considered. Specialized materials are used to ensure durability and resistance to the harsh operating environment. For example, the pins may be made of high - conductivity metals with corrosion - resistant coatings, and the barrels may be constructed from high - strength, vibration - resistant plastics or metals. Rigorous testing is conducted to ensure that the pogopin connectors meet the strict safety and performance standards required for high - speed rail, including tests for vibration resistance, temperature tolerance, and electrical performance under different conditions. By using pogopin connectors, high - speed rail systems can achieve reliable electrical connections, enhancing the overall safety, efficiency, and comfort of train travel.

Read recommendations:

Magnetic PogoPin factory customization

Magnetic connector for IoT devices

Anti - vibration magnetic connector for rugged industrial machinery